Interested in the brewing process, or know someone that is? Check out our Be the Brewer experience.

Step 1 – Mashing

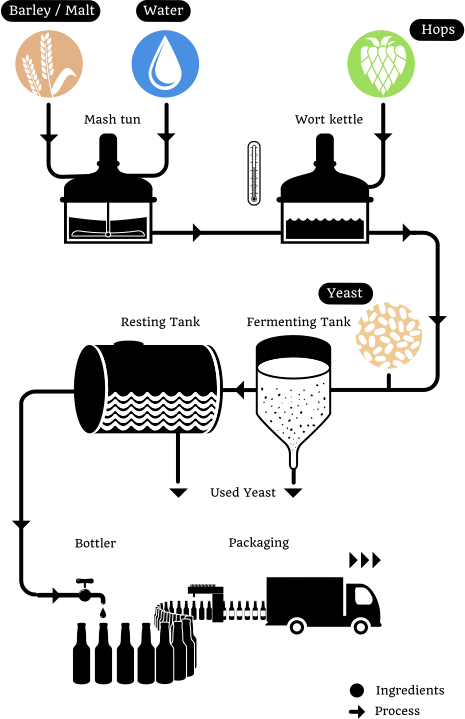

Once the style of beer has been decided, and the recipe designed, the first stage is to convert the carbohydrate in the malted grains to sugars and extract the liquid. This process is called “Mashing” and it’s completed in a large tank or vessel called a Mash Tun. The grains are added to hot water (“liquor”) at a specified temperature and mixed to a thick porridge like consistency. This mixture is allowed to stand for a period, during which time the carbohydrate in the grains is converted fermentable sugars. The resulting liquid (“Sweet Wort”) is then drained off and transferred to another vessel (“the Copper” or “Kettle”) for boiling. While the sweet wort is draining from the Mash Tun, the top of the Mash is sprayed with hot liquor (water) which drains through the grain washing out the remaining sugars.

Step 2 – The Boil

OK, so now we’ve got the Copper / Kettle filled with that beautiful hot sweet wort and what we have to do is vigorously boil the liquid so that it effectively sterilizes the wort and helps unwanted proteins and other substances to coagulate for easier removal later on. Hops are introduced at the boil stage to add bitterness and different flavours. Adding hops at the end of the boil adds aromas to the finished beer. The liquid is now referred to as “Hopped Wort”, and after a short period of standing in the Copper / Kettle it is cooled and transferred to the next vessel (“Fermentation Vessel”) for, yes ,…..you’ve guessed it…..the fermentation stage

Step 3 – Fermentation

Generally accepted as the most critical stage of the brewing process, fermentation begins when natural yeast is mixed (“Pitched”) with the cooled wort. The yeast gets to work on all those lovely natural sugars that we extracted from the grains, and converts them to alcohol and carbon dioxide. The yeast also impacts on the unique flavours found in the beer being brewed. The environmental conditions for fermentation need to be strictly controlled and monitored if consistently great craft beers are to be produced, and strict hygiene is essential to avoid spoiling the beer. The brewer will regularly check the alcohol content over the fermentation period to ensure that the finished beer in your glass ends up at the correct % ABV. Once the fermentation is complete, the liquid (now called “beer”!) is chilled and this helps the yeast to sink to the bottom of the fermentation vessel prior to transfer to either Conditioning Vessels or Casks (for Cask Conditioned beers).

Step 4 – Racking and Conditioning

Depending on how the beer is to be packaged and delivered, different methods of Conditioning are adopted. For Cask Conditioning (Real Ale), the beer is “Racked” off the sediment in the fermentation vessel and is filled directly into the sterilized cask that will be delivered to your pub. A small quantity of live yeast remains in the beer during racking, and this activates a secondary fermentation in the cask which gives the beer you drink its head, gas and sometimes sparkle. Finings are generally added at the racking stage to help the clear the beer prior to drinking. The racked beer is sealed in the cask and is allowed to Condition for a period at the brewery and finally in the cellar of your pub!